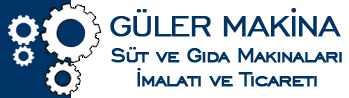

Products / Cheese Processıng Lines / Kashkaval/Mozzarella Processing Shredded/Grated Mozzarella Filling Line

Please contact our partner company MİLKOSAN ( www.milkosan.com ) for your inquiries on Shredded/Grated Cheese Filling Machines.

Mail : info@milkosan.com

WhatsApp : +90 543 778 7486

MACHINE INTENDED PURPOSE

Our newly designed integrated Shredded Cheese Filling/Packing unit is intended for filling and packaging of food and non-food products with a vertical forming of the package from heat-sealable film roll.

CHARACTERISTICS OF THE PRODUCT TO BE FILLED

Our fully automated Weighing/Portioning/Bag Filling line has been developed for the purpose of bag filling any kind of shredded/grated cheeses. But it has the capability of filling other powdered/granular foods and agricultural products (e.g. rice, oat, rye and etc..).

.UNIT EQUIPMENTS

The Fully-Automated Shredded/Grated Mozzarella Filling/Packing unit is composed of below equipments :

1- Starch Dosing/Mixing Drum (Optional)

2- Feed Conveyor Conveyor (Frequency Inverter)

-

Parameters of powersupply :

Voltage, V 220±22

Frequency, Hz 50±55

grounding TN-S or TN-C-S;

-

Installed power, max, kW 0,75

-

Height of product feeding, mm 3600;

-

Overall dimensions, mm, max: (length x width x height) 4610x 1000 x 3980

-

Weight of conveyor, max, kg - 350

-

Feeding conveyor is equipped with:

- frequency inverter;

- side fencing;

- polyurethane belt.

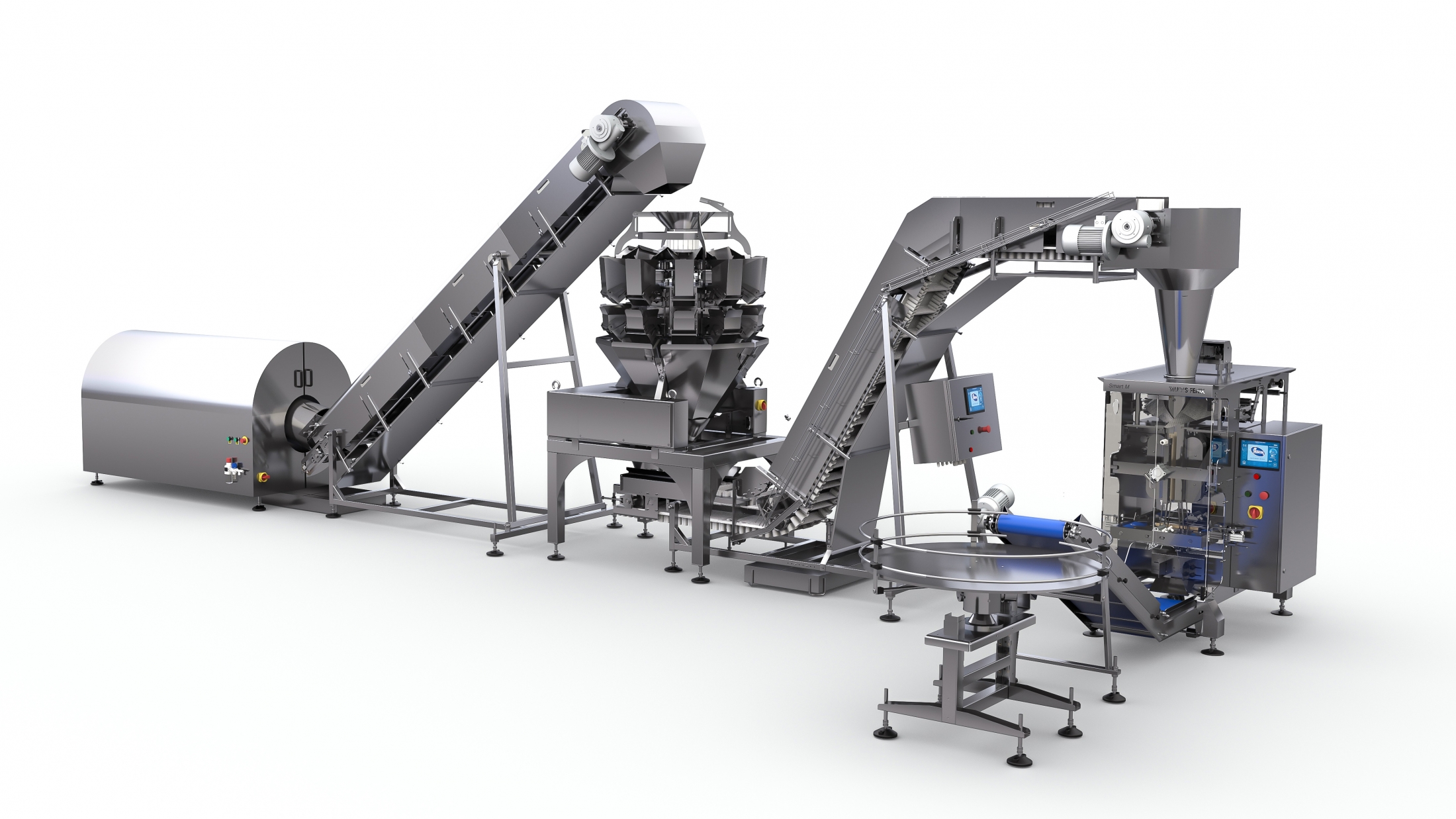

3- Combinational Weighing Platform ( Optionally can be equipped with Cleaning and Service Platform for easier maintanance and better hygienic conditions)

Type of weigher - gravimetric, combination, radial with step drives.

Number of weighing feeders: 10

The limit of dosing (one release) : from 15 gr to 1500 gr

Weight indication increment : g 0,1

Dosing accuracy according to GOST 8.579-2002 (depends on weight of single product fraction, dose weight and capacity of packaging module.)

Power supply is performed by AC network with voltage 220V±10%, 50Hz

Power consumption, kW 3,3

Overall dimensions of the weigher(length × width × height), mm 1056 × 1126 × 1329

Weight, max, kg 350

The weigher is equipped with:

Timing hopper “Duck-mouth” for dividing of doses that are discharged from the weigher;

4- Fully Automated Vertical Bag Filling Machine

Capacity : Capacity for standart line design is 2000/2400 bags-hr. Tailor made solutions are provided per your processing capacity. Actual capacity depends on the package length, characteristics materials to be used (thickness and film characteristics), product characteristics and weigher capacity and can be less than mechanical depending on the combination of factors mentioned above

Filling İnterval : 15 gr > 1500 gr

Powersupply: 380 V ± 10%, 50Hz

Installed power : 3,0 kW

Working pressure in the pneumatic system: 0,6 mPa

Acceptable pressure deviation on the air preparation unit: 0.02 mPa

Compressed air supply: not more than l/min 400

Overall dimensions of the module: mm: (length x width x height) 1500 x 1090 x 1335 mm

Weight: 430 kg.

Packaging module is equipped with:

Cross sealing jaws of constant heating without dater, seam width – 17 mm, tooth pitch – 3 mm;

Thermal printer with standard kit of digits. 1 or 2 rows with 6 digits in a row. Date can be placed on any area of bag- option;

Length compensator for date placing adjustment;

Film completion sensor;

Eyespot sensor;

Encoder for film pulling without eyespot;

Shaft with cones for film clamping;

Clamps for excess air removing;

Flat bottom unit – optional

Inert gas injection unit – optional

5- Discharge Conveyor