Products / Milk Reception And Weighing Cooling Plate Heat Exchanger

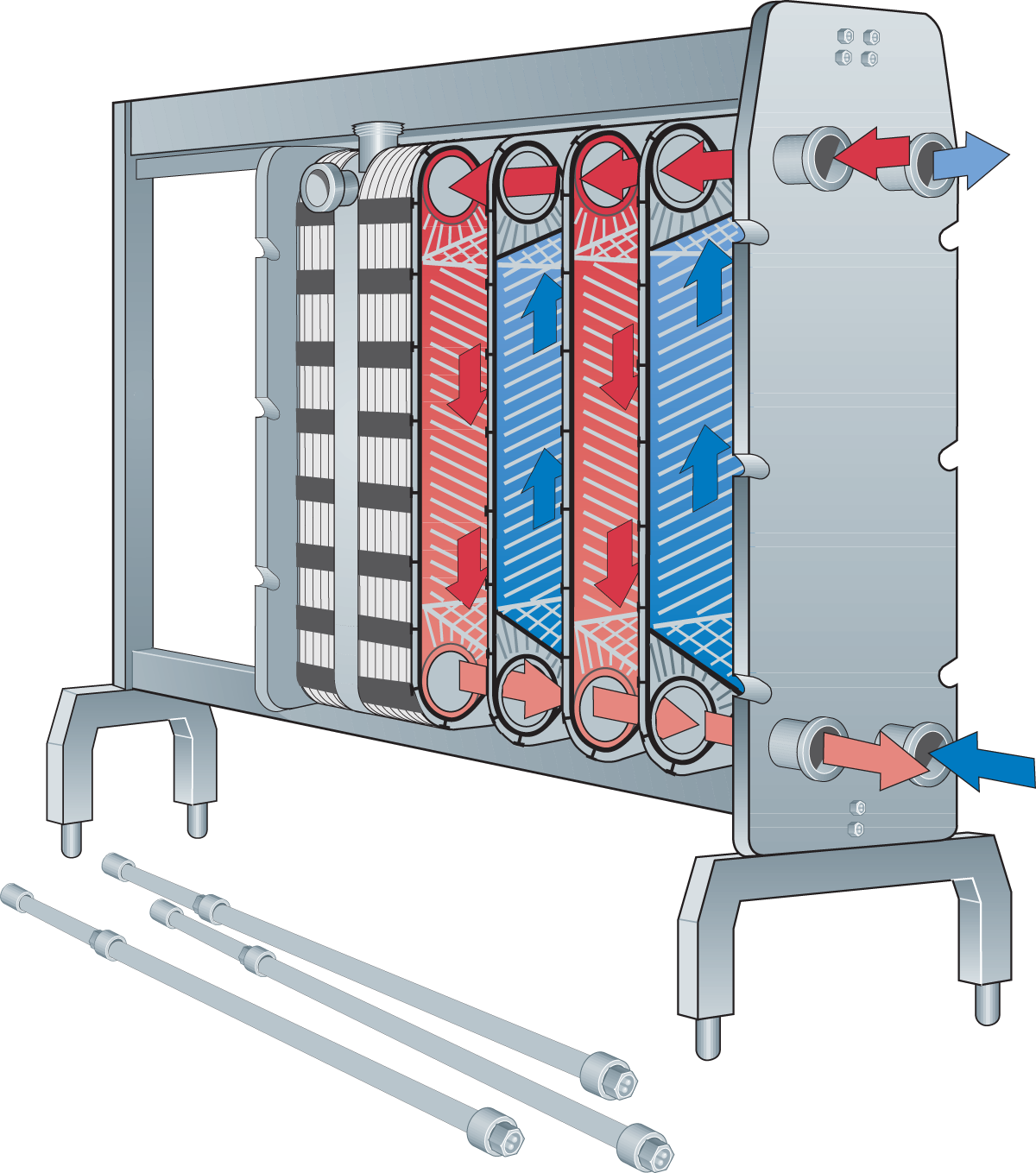

Cooling the milk soon after milking process is quite critical for protecting it from bacterial growth unwanted proteolytic activities. This will end up with a decrease on the final product quality and production yield, which makes cooling process important for both public health and economic income.

As cooling process can be performed by GÜLER Milk Cooling Tanks, it is also possible and even easier-faster with Cooling Plate Heat Exchangers.

Cooling PHEs are mostly preferred by high-capasity plants with day-long continuous reception of milk.After cooling the milk via PHEs, it is pumped into GÜLER Milk Storage Tanks and kept under cold/safe conditions by the isolation layer covering the tank.

|

Capasity

|

Min: 500 lt-s Max: 30000 lt-s

|

|

Plate Type

|

AISI316 L - Titanium

|

|

Gasket Type

|

NBR - EPDM - VITON

|

|

Frame

|

Stainless Steel ( Covered-Solid)

|

|

Connections

|

Rubber Insert / Flanş

|

|

Cooling Media

|

Chilled Water

|